Safety and health are top priorities during flights to and from mining sites, given the inherent risks of the industry. Safe transport of personnel and mining goods involves strict safety measures and protocols that cater to the unique aspects of the mining sector. This guide by CASAIR discusses the key safety practices and health protocols necessary for mining flights, demonstrating their role in enhancing the security and efficiency of these operations.

Personnel safety

Ensuring the safety of personnel on mining flights starts with strict adherence to aviation safety standards. This includes rigorous checks and maintenance of aircraft, thorough training for all flight crew, and the enforcement of safety protocols among passengers. Crew members are trained to handle potential emergencies specific to mining operations, such as rapid changes in weather conditions and landing on less conventional airstrips. Passenger safety is reinforced through several measures:

Pre-flight safety briefings

Before each flight, passengers are briefed on the specific risks, weather conditions, and emergency procedures tailored to that flight’s particular dynamics.

Mandatory use of personal protective equipment (PPE) when required

Passengers must wear helmets, safety goggles, and hearing protection to shield against physical injuries and environmental hazards.

Familiarisation with the aircraft’s safety features

Passengers receive instructions on using the aircraft’s safety equipment, including seatbelts, oxygen masks, and the location of emergency exits.

Health considerations

The health of passengers is another critical aspect. Mining flights often operate in remote areas under varying environmental conditions, which can pose health risks. Key practices include:

Medical supplies and crew training

Every flight is equipped with essential medical supplies, and at least one crew member is trained in first aid, ready to respond to health emergencies.

Protocols for air quality and cabin pressure

Protocols are in place to maintain optimal air quality and cabin pressure, protecting passengers from potential health issues during the flight.

Transporting mining goods

The safe transport of mining goods is crucial not only to prevent financial loss but also to ensure the safety of the aircraft and all its occupants. Different types of mining products, require specific handling procedures to ensure they are transported without accidents.

Packaging and containment

Mining goods must be securely packed and contained to prevent shifting during flight, which could destabilise the aircraft. Measures include:

Packaging and containment

Mining goods are packaged in containers that are strongly built to withstand the rigours of flight and adequately sealed to ensure that no material escapes during transit. These containers are designed to maintain the integrity of the contents, preventing any leakage of hazardous materials. Each container is also clearly labelled with handling instructions and hazard warnings, ensuring that they are handled correctly and safely throughout the journey.

Leakage prevention

Containers are specifically designed to prevent the leakage of hazardous materials, ensuring they do not pose a risk to the safety of the aircraft or its occupants.

Labelling and handling

Every container is clearly labelled with detailed handling instructions and hazard warnings. This ensures correct handling procedures are followed and risks are well communicated to all handling personnel.

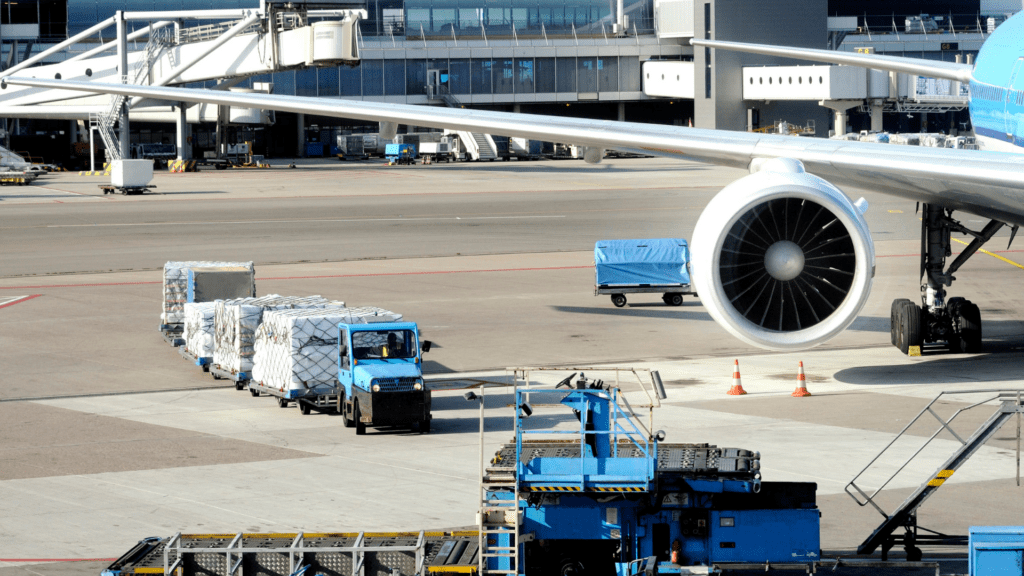

Handling and loading

The loading and unloading of mining goods are carried out under strict supervision. Best practices include:

Specialised loading equipment

Heavy or awkward loads are managed with specialised loading equipment. This machinery is designed to safely handle and secure cargo, preventing any shifts during the flight that could affect the aircraft’s stability.

Personnel training

All personnel involved in the loading process are extensively trained in safe loading techniques. This training includes understanding the specific requirements of different types of cargo, such as hazardous materials or delicate machinery, and ensuring they are handled and secured appropriately.

Cargo weight distribution

Careful planning goes into the distribution of cargo weight across the aircraft. This is essential for maintaining the balance and stability of the aircraft during flight. Proper weight distribution prevents any uneven load that could potentially compromise the aircraft’s navigational ability.

Monitoring and tracking

Advanced tracking systems are used to monitor the condition and location of mining goods throughout the flight. These systems help in:

Environmental control

The cargo hold is equipped with systems to regulate temperature and humidity, maintaining conditions within safe limits. This is crucial for preventing damage to sensitive materials, especially those that are temperature-sensitive or susceptible to moisture.

Real-time cargo monitoring

Advanced tracking systems provide real-time data on the status of the cargo. This capability is vital for quickly identifying and responding to any issues that might arise during transport, such as shifts in cargo position or changes in environmental conditions within the cargo hold.

Regulatory compliance

Compliance with national and international regulations is fundamental to the operation of mining flights. Regulatory bodies set standards that cover everything from the technical maintenance of aircraft to the qualifications of flight personnel and the handling of hazardous materials. Operators must ensure:

Regular audits and inspections

Competent authorities conduct regular audits and inspections to ensure that all operational and safety protocols are followed. These checks verify the condition of the aircraft, the adherence to safety standards, and the proper handling and storage of cargo.

Certification maintenance

It’s essential that all necessary certifications for aircraft, equipment, and personnel are kept up-to-date. This includes certifications for safety management, hazardous material handling, and aviation operation standards.

Continuous training and assessment

All staff involved in mining flights undergo continuous training and assessment. This training ensures that they are competent in the latest safety procedures and emergency response techniques. Regular assessments help maintain high standards of safety and operational efficiency.

Conclusion

The rigorous safety and health practices implemented on mining flights are critical for the protection of personnel and the secure transport of mining goods. By adhering to high standards of safety, conducting thorough pre-flight checks, and ensuring continuous training and regulatory compliance, mining flight operators can mitigate risks and maintain operational efficiency.

For companies looking to enhance their mining operations, choosing a trusted and experienced air charter service like CASAIR, which upholds the highest safety standards and customises solutions to meet specific mining needs, is essential. Get in touch today to explore how CASAIR can assist with your mining flight requirements and ensure the highest safety standards.